Cement Works

The Cement Making Industry

North Kent was the centre of experimentation and innovation, and that with its advantages in the form of raw materials, cheap water transport and markets; it became the leading centre of production of Roman and Portland cement.

The need for a strong reliable cement increased due to the escalating engineering works from the late 18th century onwards.

James Parker, in 1796, patented what became known as Roman cement. This was a ‘natural’ cement made from chalk and clay in approximately the right proportions, which, when broken and fired in a kiln at 900 to 1200 degrees centigrade, and ground to a powder with mill stones and sieved, produced a strong cement.

The ‘cement stones’ were initially obtained from the Sheppey shore, the Essex coast and by dredging between.

Parker produced Roman cement at Northfleet, his works quickly passing into the hands of the Wyatts, and in 1846 to Maude, Jones and Joseph Aspdin.

As soon as Parker’s patent ran out in 1810 the Roman cement industry spread along the Thames and elsewhere in the country where the ‘cement stones’ were available. Due to the limited availability of the ‘cement stones’, experiments continued to create an ‘artificial’ cement.

In 1822 James Frost patented ‘British’ cement, which he produced at Swanscombe from 1825.

In 1824 Joseph Aspdin of Leeds patented ‘Portland’ cement with a process which appeared to involve slaking lime before adding clay, but otherwise similar to Frost’s process.

However, this early cement was not a fully reliable product as it was not produced at a high-enough temperature to be the real forerunner of modern Portland Cement and it wasn’t until the mid 1800’s when Aspdin's son William, in 1843, made an improved version of this cement and he initially called it "Patent Portland cement" although he had no patent.

In 1848 William Aspdin further improved his cement and in 1853 he moved to Germany where he was involved in cement making.

In 1845, I.C. Johnson, the works manager at J B White, Swanscombe, utilised vitrified clinker to make a superior cement by firing a mixture of chalk and clay at much higher temperatures (1400C-1500C) , similar to those used today.

Both lay claim to being the first to create Portland cement with Joseph being accepted as the first to manufacture a type of Portland cement. It is, however, Issac Johnson who used the same components as we do today only differing by failing to utilise the three important developments for Portland Cement of today. That is to say the addition of gypsum to control setting, the use of ball mills to grind clinker and the development of rotary kilns.

For more information please refer to 'The Cement Industies 1796 - 1914' by A.J. Francis pub. 1977

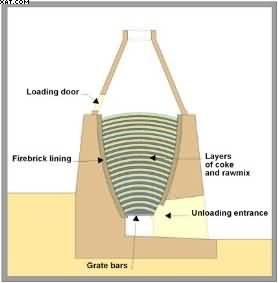

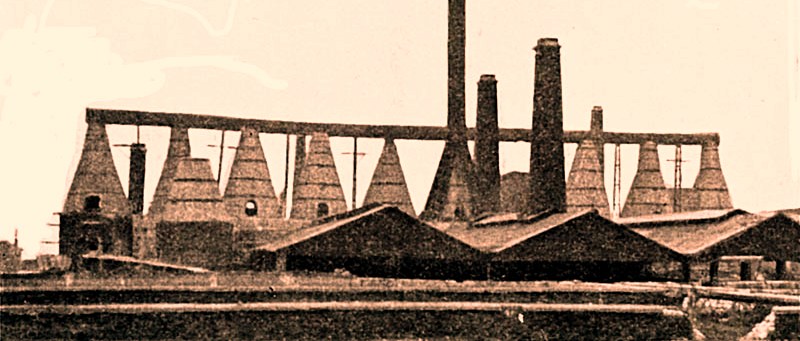

Chamber Kiln Courtesy of Dylan Moore

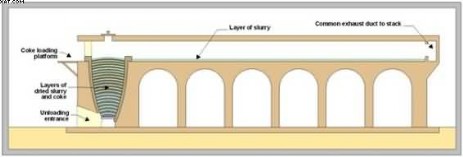

Bottle kiln. Courtesy of Dylan Moore

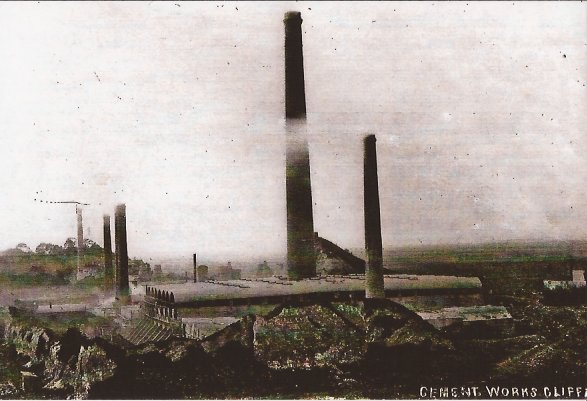

The Pottery (Cliffe Creek Cement Works)

1854 - 1886

The 'Pottery' was the first cement workings to be built at Cliffe.

First owned by I.C. Johnson & Co. from 1854 - 1876. It was then bought, as a going concern, by Empson, Holcombe & Co in 1876 who held it for ten years until it was finally bought by Francis & Co. Ltd. who promptly closed it down and it was replaced by Cliffe Quarry.

It began life with two bottle kilns which was increased to five by 1856. In 1863 this was increased to ten and finally increasing to sixteen in 1868. During its operation no rotary kilns were installed.

Close to the cement works was the whitening factory (the 'Chalk House' ~ as referred to on a tithe map) which had been built prior to 1842.

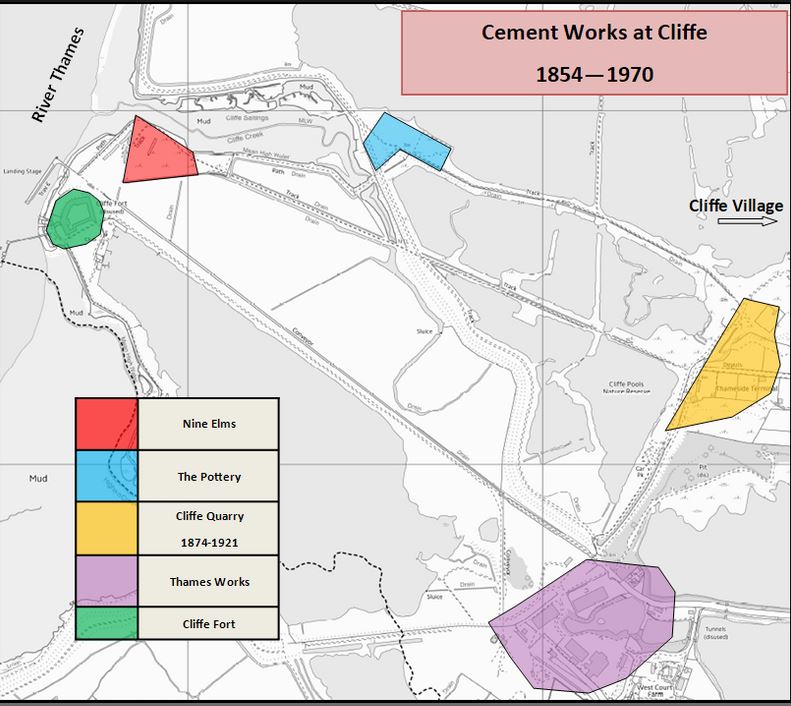

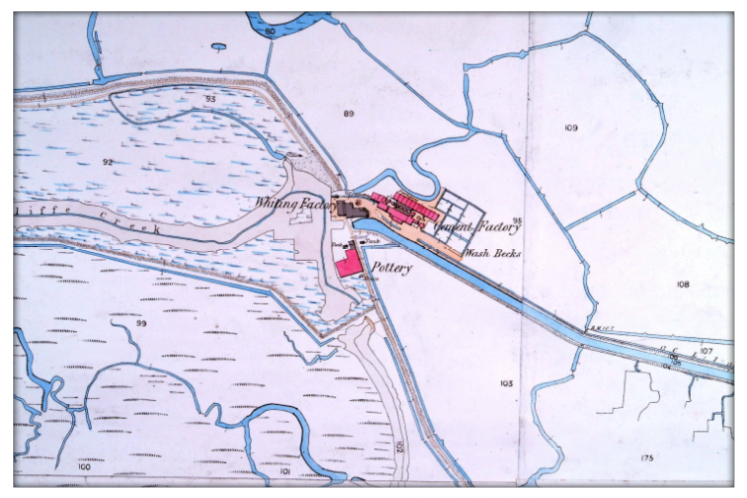

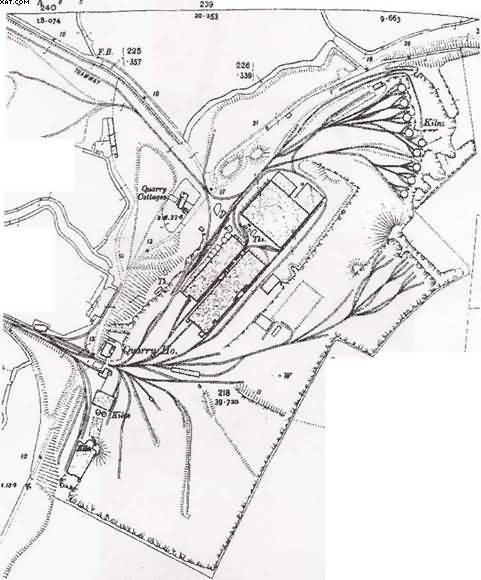

Map showing the site of Nine Elms Works, The Pottery and Whitening Works

Nine Elms (Cliffe Creek, Francis & Co. Cement Works)

1867 - 1900

Further downstream from The Pottery, along Cliffe Creek, Francis & Co. established a new cement works in 1867. The previous year Francis & Co negotiated a lease for some 15 acres of land for a tramway and wharf on land between the Creek and the MOD (War Department).

Alfred Francis, the founder of the company, died in 1871 but his sons, Charles Larkin and Alfred, carried on the family connection and continued to produce 'Portland, Roman, Medina, and Parian cement, Portland stucco and Plaster of Paris', also shipping chalk, flints and fire bricks, from the site. In 1881, Alfred Francis, owner of the Nine Elms works across Cliffe Creek, appears to have acquired an acre of land near the old pottery, possibly to establish a public house - he is listed in 1882 as a beer retailer.

The riverside location provided ease of transport and wharves were duly built at the mouth of Cliffe creek. A canal was constructed from the works, which gave its name to a tavern built nearby, now long demolished but remembered as the Canal Tavern.

1870-1 saw further developments to the cement works, which were rebuilt and extended, with an elaborate tramway Methods of extracting the chalk were basic, involving the labourer being suspended by a rope (around his waist) secured at the cliff top, from which position he would hack out the chalk, so that it fell to the ground below to be collected in a waiting railway wagon.

1886 Francis & Co. amalgamated with Johnson Whiting and Empson, Holcombe & Co. to operate under one single ownership as Francis Co. Ltd. At the turn of the century Francis & Co Ltd. joined the Associated Portland Cement Manufacturers (APCM): the forerunner of Blue Circle.

It was at this time that the cement works at Nine Elms started to close down.

The kiln block of 1866-8

During its operation it began with nine bottle kilns to which a further ten were added. The kiln block of 1866-8 can still be seen today together with a grinding mill base a possible prototype for the Johnson chamber kiln.

Cement manufacturing finally ended by 1921 and whiting production by the 1930's.

All that remains of the kiln block as it looks now.

A view of inside the kiln.

The remains of the grinding base. Inside the kiln

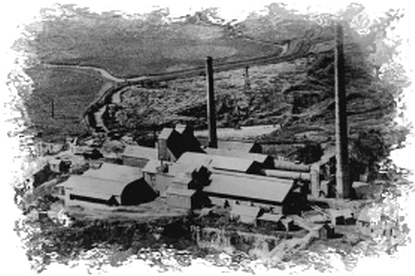

Cliffe Quarry (Johnson's Cement Works)

1874 - 1921

1874 - 1921

Site of Cliffe Quarry Cement Works

The quarry was already in existence for use by the Cliffe Creek Whiting Works and comprised of a range of kilns.

It was owned by I.C. Johnson & Co. between 1874 & 1886 and then by Francis & Co. until the turn of the century. From 1900 to 1921 it was owned by APCM (Blue Circle).

The plant was built to replace the Cliffe Creek site which Johnson sold to Empson, Holcombe and Co.

There were sixteen chamber kilns. During the period 1874-1886, a total of nine Michele chamber kilns were built in the south part of the site, which was owned by Francis. After the rest of the plant was purchased by Francis, a further six kilns were added to the northern block in 1898.

After closure, the whiting plant, on the creek opposite the old works, continued in operation.

Much of the original site was built over by an oil depot.

Thames Works (Alpha Cement Works)

1912 - 1970

The Thames Portland Cement Company started constructing cement works to the south of the Quarry in 1910, with production commencing in 1912-3 with one rotary kiln, and a tramway to a jetty adjacent to Cliffe fort. A second rotary kiln was added in 1926.

The works became the Alpha Cement Works in 1934, with a third kiln added in 1936 and a fourth in 1938. part of Associated Portland Cement Manufacturing (Blue Circle) 1949, the Alpha works remained in production until closure in 1970.

During the digging for mud in the mid 1930's, apart from some concern raised by The Kent Rivers Catchment Board due to the close proximately to the sea walls, much in the way of important archaeological finds were cast aside or completely destroyed.

It is here that it is strongly believed that the Saxon settlement of Herodham was located, as well as a Roman settlement, as it was here that finds of a Roman alter and yet another Roman cemetery, comprising a number of inhumations together with several cremation urns were uncovered.

View of Cliffe Creek from Nine Elms Plant looking towards The Pottery and Whitening Works.

Sources

Bellis, M The History of Concrete and CementFrancis, A.J. 'The Cement Industies 1796 - 1914' (1977)

Moore, D. www.cementkilns.co.uk

Winter, N www.understanding-cement.com

Poertland Cement Association, History & Manufacture of Portland Cement

Assessment Report of Francis Quarry Cliffe, Kent (2009 & 2110), R.S.P.B.